A Selection From Our Projects

KRM-4 used in the world’s widest bandwidth radio astronomical receiver

Metsähovi Radio Observatory uses KRM-4 in the world’s widest bandwidth radio astronomical receiver Photo by Mikko Raskinen Researchers [...]

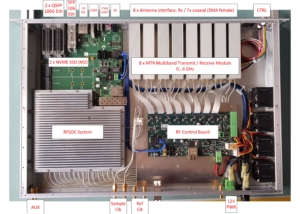

IAF – KRM-4 Broadband 8-channel SDR transceiver

IAF - KRM-4 Broadband 8-channel SDR transceiver IAF GmbH in Braunschweig, Germany uses our RFSoMs KRM-4ZU47DR or KRM-4ZU48DR in their [...]

RF – test platform utilizing four KRM-4 RF-SoC modules

RF Test system featuring four RFSoC Modules To automate the testing of a very complex RFSoC carrier design, [...]

Multi FPGA compute acceleration PCIe card

Multi FPGA PCIe acceleration card with sizeable non volatile storage

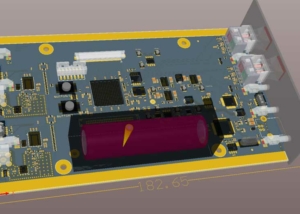

Robot Swarm

A swarm of custom robots with a novel precision optical tracking system and real time image processing in FPGA

OFDM SDR Radio front end

OFDM SDR Radio Front End design with high speed converters and extremely low jitter requirements

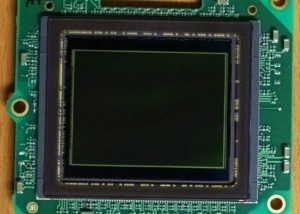

50 MegaPixel Image-Sensor Evaluation Platform

Evaluation of the optical and electrical characteristics of a mid- format 50 Megapixel CMOS image sensor.

48 Channel Motor Control

FPGA based 48 Channel Motor and actuator control with tight time synchronization

ISM Band Radio Modem with POF link

Dual Channel full duplex ISM band RF modem with FPGA based data router and Plastic optical fiber data link

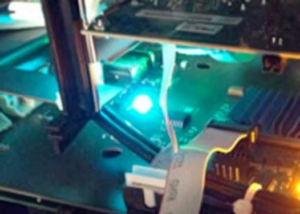

LOW LATENCY FIBEROPTIC VIDEO & DATA LINK

Low latency Fiber-optic Data & Video link with 2 microsecond round trip latency for data packets

LED color video panels

LED video panel tiles, scalable, deep color, 600Hz refresh rate